Abrasive Materials Cut Wire Zinc - China Manufacturers, Suppliers, Factory

To be a result of ours specialty and service consciousness, our company has won a superb reputation between customers all around the environment for Abrasive Materials Cut Wire Zinc, 304 Stainless Steel Cut Wire Shot 0.5mm, Size Of Stainless Steel Shot, Stainless Steel Cut Wire Shot 0.3mm,Pin On Aluminum Cut Wire. We welcome new and previous customers from all walks of lifestyle to contact us for long run organization relationships and mutual achievements. The product will supply to all over the world, such as Europe, America, Australia,Mauritania, Kazakhstan,Israel, Niger.Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

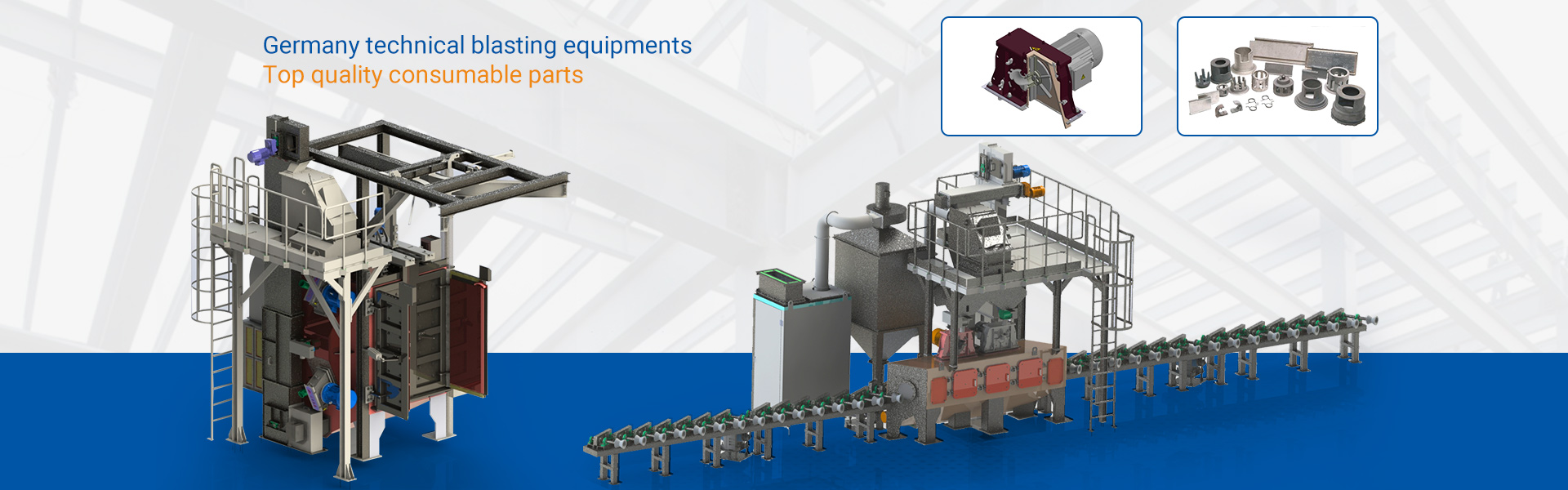

Related Products