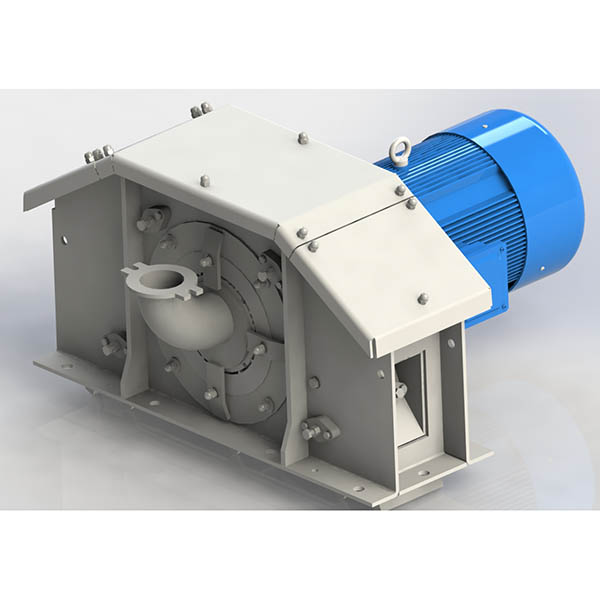

Best-Selling Blade - Blast wheels – TAA

Best-Selling Blade - Blast wheels – TAA Detail:

TAA high performance blast wheel have proven themselves on the market to be robust, economically efficient and maintenance-friendly. They are available with different turbine wheel diameters and a variety of spare and wear materials (e. g. hard metal).

TAA high performance blast wheels are very popular for modernizing conventional shot-blasting machines as well.

Product Features

Improving shot blasting speed obviously

Good wear resistance

Reducing energy consumption greatly

Extraordinary service life

Suitable structure

High cleaning quality

Low consumption of steel shot

Low abrasion of parts

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Best-Selling Blade - Blast wheels – TAA , The product will supply to all over the world, such as: Porto, Tajikistan, Ecuador, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

Write your message here and send it to us