Providing top quality abrasives

LEADING PRODUCTS

-

Low Carbon Steel Shot

Product feature High strengthen, high tenacity, long service life. Low breakage, low dust, low pollution. Low wear of the equipments, long life of accessory. Reduce dedusting system load, lengthen usage time of dedusting equipments. Technical specification Chemical Composition% C 0.10-0.20% Si 0.10-0.35% Mn 0.35-1.50% S ≤0.05% P ≤0.05% Other alloy elements Adding Cr Mo Ni B Al Cu etc. Hardness HRC42-48/48-54 Microstructure Duplex structure co...

-

Stainless steel grit

Features * Can be used to replace a variety of mineral sands & non-metallic abrasives,such as corundum, silicon carbide, arenaceous quartz, glass beads, etc. * Low dust emissions,improving operating environment, environmental friendly. * Can replace part of the pickling process. * Low dust emission and excellent operating environment, reducing the treatment of pickling waste. * Low comprehensive cost, the service life is 30-100 times that of non-metallic abrasive such as corundum. * Can B...

-

Stainless steel cut wire shot

Stainless steel cut wire shot is widely used for the shot/air blasting of various types of non-ferrous metal castings, stainless steel products, aluminum parts, hardware tools, natural stone, etc, highlighting the metal color and achieving smooth, rust-free, matt fi nishing surface treatment eff ect. With good quality stainless steel wire raw material, stainless steel shot is featured with uniform particles and hardness, which guarantees its long service life and good blasting eff ect. The pe...

-

Carbon steel cut wire shot

We made great improvement in material and the techniques on the basis of the traditional production process. Utilizing high quality alloy steel wire as the substrate that higher the mechanical properties and make it more stable. Improving the wiredrawing craft which make the internal organization more dense. Improving the traditional passivation process that completely relying on impacting to reduce the damage during blasting, enhancing the service life. Item Technical index Chemi...

-

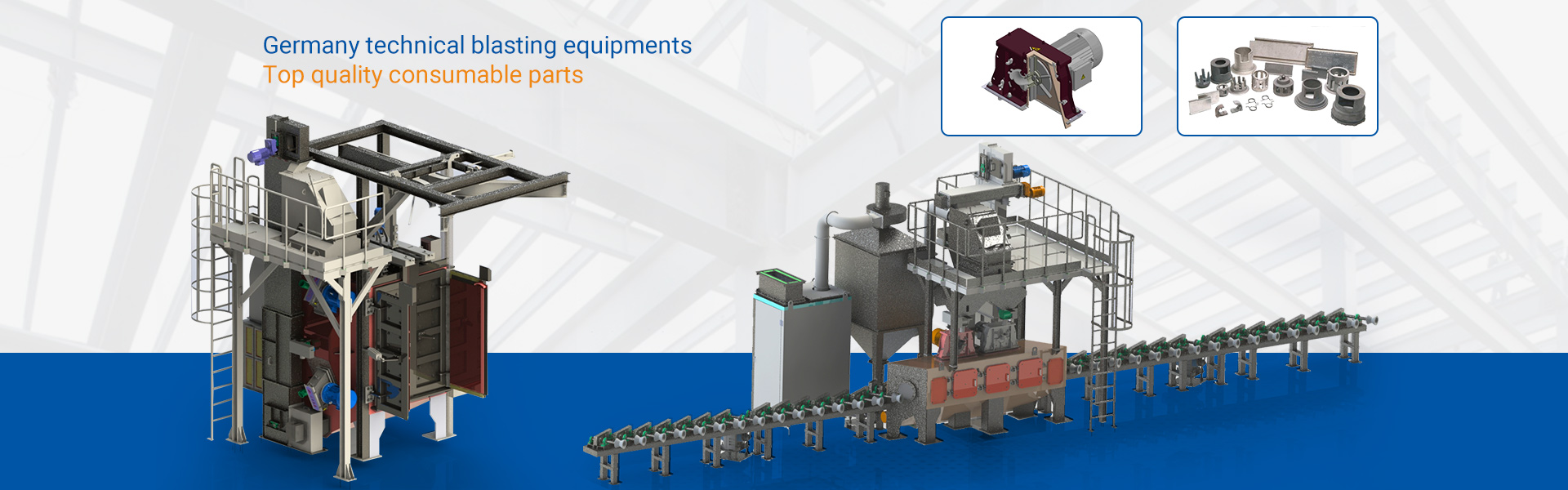

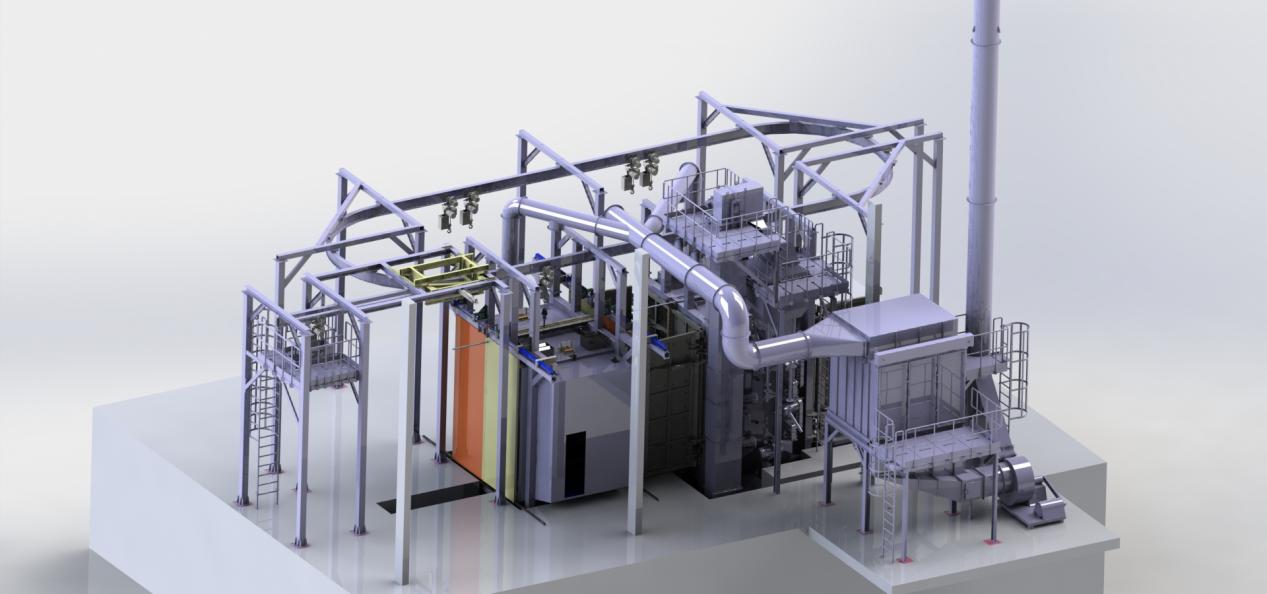

Drum type shot blast machine

Advantages of drum shot blast machine Reliable Blasting Technology: Drum shot blast machines are manufactured in several different variants, types and sizes. They are compact and only have a very small footprint. Continuous throughput can be realised by linking several machines. Maintenance-friendly Layout: Regular maintenance is important for preserving the long-term value of the equipment. Large service and inspection doors provide easy access to all of the important components. As a result...

-

Grinding wheels FW-09 series

Our super-hard alloy tools are produced by brazing. Under certain conditions, a layer of diamond is firmly welded to the metal substrate after a metal solder melting process. This type of product has the characteristics of high grinding efficiency, long service life, safety, environmental protection and pollution-free. Mainly replace the current resin bond corundum cutting and polishing tools, all coarse and medium coarse-grained electroplated diamond tools, and some hot-pressed sintered diam...

-

Sponge media abrasives

Sponge Media abrasive are available in over 20 types,achieving profiles from 0 to 100+ micron. All procides dry, low dust, low rebound blasting. The most commomly used is TAA-S series with aluminum oxide and TAA-G series with steel grit. Type Profiles Abrasive Media Agent Application TAA-S#16 ±100 micron Aluminum Oxide#16 Fast and aggressive for tough industrial coatings. TAA-S#30 ±75 micron Aluminum Oxide#30 Removal of multilayer coatings and profile to 75 micron. TAA-S#30 ±50 micro...

-

Bearing steel grit

Compared with traditional steel grit made by crushing steel shot, bearing steel grit has the following Features: Raw Material Bearing steel grit is made by Chromium bearing steel which has good harden ability due to its high content of Chromium. Technology Bearing steel grit is made by crushing the forged bearing steel directly which is free from casting defects. Low wear The forged state bearing steel grit with sharp edges has higher mechanical property than traditional cast steel grit with...

Trust us, choose us

About Us

Brief description:

ZIBO TAA METAL TECHNOLOGY CO., LTD is the leading manufacturer of blasting abrasives in China and one of the top third suppliers all over the world. Founded in 1997, TAA has been awarded as National Hi-Tech Enterprise, owning the only metal abrasive engineering technology research center in China.

Relying on the research center, TAA has continuously developed many high-performance products more suitable for customers,including:low carbon bainite steel shot, low carbon bainite mixed abrasives, stainless steel cut wire shot, stainless steel grit etc.