China Cheap price Hook Shot Blasting Machine - Blast wheels – TAA

China Cheap price Hook Shot Blasting Machine - Blast wheels – TAA Detail:

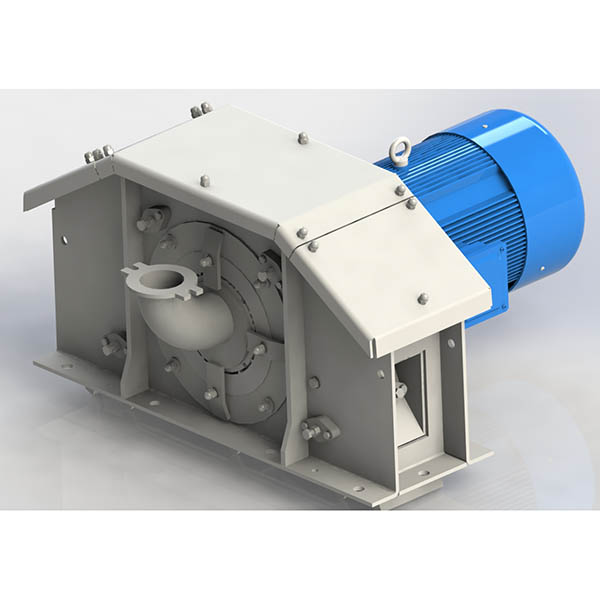

TAA high performance blast wheel have proven themselves on the market to be robust, economically efficient and maintenance-friendly. They are available with different turbine wheel diameters and a variety of spare and wear materials (e. g. hard metal).

TAA high performance blast wheels are very popular for modernizing conventional shot-blasting machines as well.

Product Features

Improving shot blasting speed obviously

Good wear resistance

Reducing energy consumption greatly

Extraordinary service life

Suitable structure

High cleaning quality

Low consumption of steel shot

Low abrasion of parts

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency profits team values customers' requirements and organization communication for China Cheap price Hook Shot Blasting Machine - Blast wheels – TAA , The product will supply to all over the world, such as: Austria, Irish, Thailand, We provide OEM services and replacement parts to meet the varying needs of our customers. We give competitive price for quality solutions and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Write your message here and send it to us