China wholesale Sand Blasting Machine - Blast wheels – TAA

China wholesale Sand Blasting Machine - Blast wheels – TAA Detail:

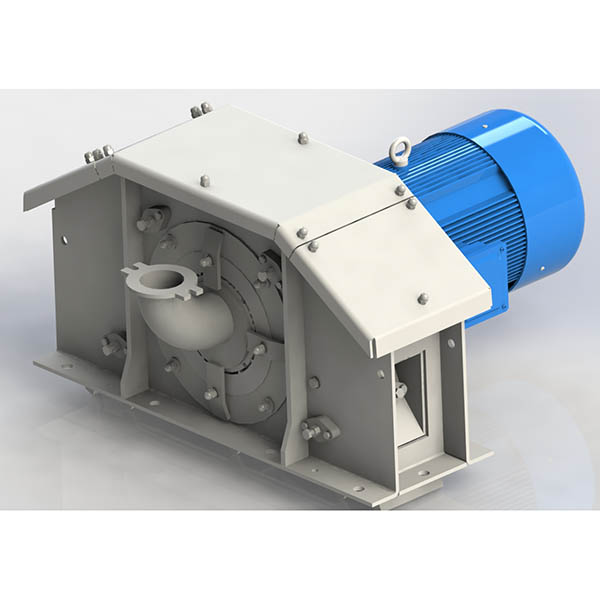

TAA high performance blast wheel have proven themselves on the market to be robust, economically efficient and maintenance-friendly. They are available with different turbine wheel diameters and a variety of spare and wear materials (e. g. hard metal).

TAA high performance blast wheels are very popular for modernizing conventional shot-blasting machines as well.

Product Features

Improving shot blasting speed obviously

Good wear resistance

Reducing energy consumption greatly

Extraordinary service life

Suitable structure

High cleaning quality

Low consumption of steel shot

Low abrasion of parts

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for China wholesale Sand Blasting Machine - Blast wheels – TAA , The product will supply to all over the world, such as: Chile, Myanmar, Vietnam, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

Write your message here and send it to us