factory Outlets for 410 0.4mm Stainless Steel Cut Wire Shot - Stainless steel cut wire shot – TAA

factory Outlets for 410 0.4mm Stainless Steel Cut Wire Shot - Stainless steel cut wire shot – TAA Detail:

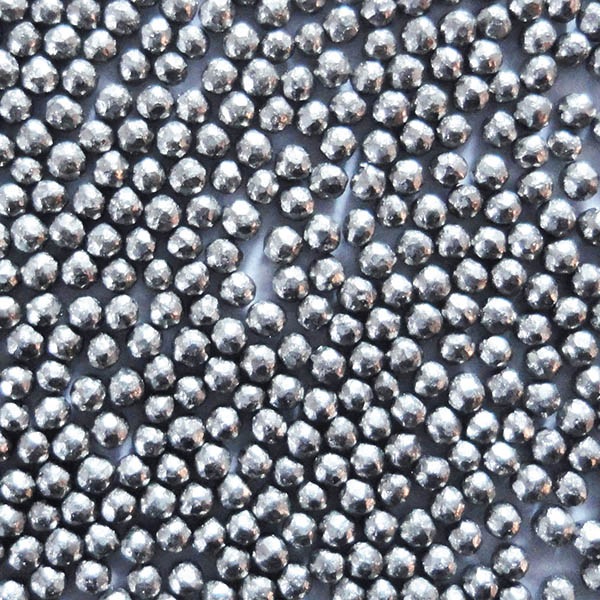

Stainless steel cut wire shot is widely used for the shot/air blasting of various types of non-ferrous metal castings, stainless steel products, aluminum parts, hardware tools, natural stone, etc, highlighting the metal color and achieving smooth, rust-free, matt fi nishing surface treatment eff ect. With good quality stainless steel wire raw material, stainless steel shot is featured with uniform particles and hardness, which guarantees its long service life and good blasting eff ect. The pellets after conditioning have low wear to the blasting machines.

Stainless steel cut wire

Stainless steel cut wire G1

Stainless steel cut wire G2

Stainless steel cut wire G3

Stainless steel cut wire-As cut, cylindrical

G1 Shape-After the treatment for cut surface’s edges, to get the edges passivated

G2 Shape-Semi conditioned

G3 Shape-Get rid of all the edges to make it become ball type, almost spherical

Technical specification

|

SUS304 |

SUS430 |

SUS410 |

|||||

|

Chemical Composition |

C |

≤0.08% |

≤0.12% |

≤0.15% |

|||

|

Si |

≤1.00% |

≤1.00% |

≤1.00% |

||||

|

Mn |

≤2.00% |

≤1.00% |

≤1.00% |

||||

|

S |

≤0.030% |

≤0.030% |

≤0.030% |

||||

|

P |

≤0.045% |

≤0.040% |

≤0.040% |

||||

|

Cr |

18-20% |

16-18% |

11.5-13.5% |

||||

|

Ni |

8-11% |

/ |

/ |

||||

|

Hardness |

HRC38-52 |

HRC25-35 |

HRC20-30 |

||||

|

External form |

Cylindrical/Spherical |

||||||

|

Microstructure |

Austenitic |

Ferrite |

Deformed martensite |

||||

|

Density |

≥7.80g/cm3 |

||||||

Advantages

Produces with very bright surfaces

Dust free surfaces and lower dust when blasting

Longer life than cast abrasives and carbon cut wire shot

No ferrous contamination

No hollow,splits or twins

Available “as cut” or “conditioned”

Available sizes: 0.3mm,0.4mm,0.5mm,0.6mm,0.8mm,1.0mm,1.2mm,1.4mm, 1.5mm

Packing: 25kgs/bag,40bags/wooden pallet or as request.

Product detail pictures:

Related Product Guide:

Our company has been focusing on brand strategy. Customers' satisfaction is our best advertising. We also supply OEM service for factory Outlets for 410 0.4mm Stainless Steel Cut Wire Shot - Stainless steel cut wire shot – TAA , The product will supply to all over the world, such as: Mozambique, Canada, Bangladesh, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.