Factory Price For Sand For Sand Blasting Machine - Blast wheels – TAA

Factory Price For Sand For Sand Blasting Machine - Blast wheels – TAA Detail:

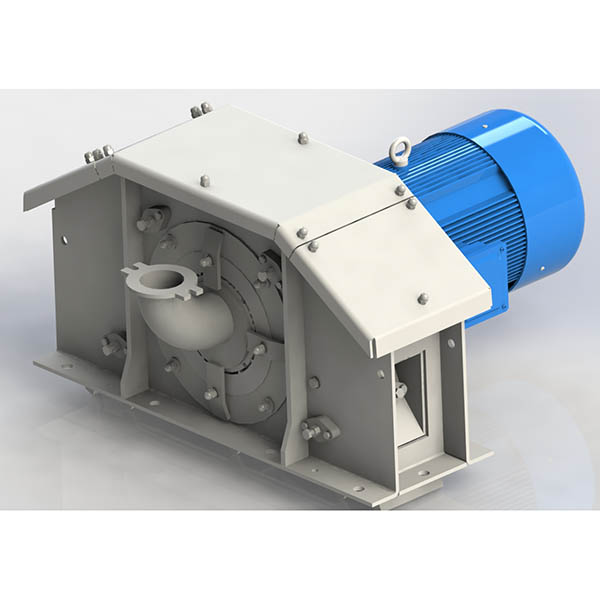

TAA high performance blast wheel have proven themselves on the market to be robust, economically efficient and maintenance-friendly. They are available with different turbine wheel diameters and a variety of spare and wear materials (e. g. hard metal).

TAA high performance blast wheels are very popular for modernizing conventional shot-blasting machines as well.

Product Features

Improving shot blasting speed obviously

Good wear resistance

Reducing energy consumption greatly

Extraordinary service life

Suitable structure

High cleaning quality

Low consumption of steel shot

Low abrasion of parts

Product detail pictures:

Related Product Guide:

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Factory Price For Sand For Sand Blasting Machine - Blast wheels – TAA , The product will supply to all over the world, such as: Cannes, Rio de Janeiro, Barbados, We have a professional sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique products.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

Write your message here and send it to us