Leading Manufacturer for Wheel Shot Blasting - Rubber belt Tumble Belt Shot Blast Machines – TAA

Leading Manufacturer for Wheel Shot Blasting - Rubber belt Tumble Belt Shot Blast Machines – TAA Detail:

Advantages of AGTOS rubber belt tumble blast machines

Reliable blasting technology

Innovative filter technology

Many different variants

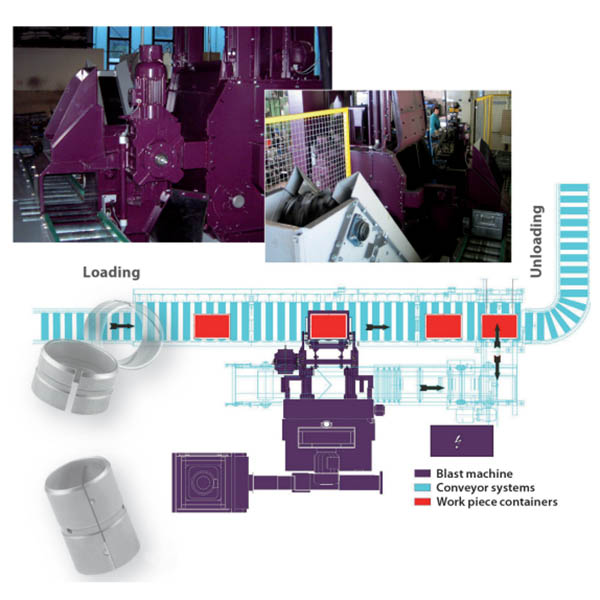

Automation through harmonisation with in-house transport system.

AGTOS high-performance turbines: Our turbines are solid, well-constructed pieces of machinery. Due to a smaller number of wear parts and high abrasive throughput, they operate extremely economically.

Many different variants: Because of the many different variants, it is possible to build the optimal blast machine for the intended application.

Automation: Machines can be optimally integrated with in house logistics systems. Custom solutions using special containers have already been successfully implemented.

Dual-purpose machine for mass production and individual parts.

The MGDT blast machine is character ized by a high degree of flexibility.

It is used to clean turned and milled parts after hardening. The machine’s belt has a load capacity of 400 kg for mass production parts with an individual weight of up to 15 kg. The turntable is used to clean impact-sensitive parts (e.g., armature shafts for electrical appliances). The table has a diameter of 680 mm and a load capacity of 150 kg.

Rubber belt tumble blast machines are available in the following standard sizes

| Specifications | MG 50 | MG 90 | MG 180 | MG 270 | MG 350 | MG 550 |

| Fill capacity (1) | 50 | 90 | 180 | 270 | 350 | 550 |

| Belt dimensions tp x width in mm 0x®g (ft*) | 500×700 | 600×800 | 800×900 | 800×1.350 | 1,000×1.350 | 1.200×1.200 |

| Max.single work piece weight (kg) | 10 | 10 | 15 | 25 | 25 | 25 |

| Max.weight of load(kg) | WO | 200 | 400 | 600 | 800 | xooo |

| Work piece transport | Optional | Optional | Optional | Optional | Optional | Optional |

| Abrasive conveyor system | Screw | Vibrating conveyor or screw | Vibrating conveyor or screw | Vibrating conveyor or screw |

Vibrating conveyor or screw |

Vibrating conveyor or screw |

| Turbine (number x kw) | 1×5,5 1×7,S | 1×7,S | M7,S 1×11 | 2×7,5 2×11 |

2×11 2×18,5 |

2×11 2×18,5 |

| Loader | Optional | Optional | Optional | Optional | Optional | Optional |

| Filter unit | PF 4/4 | PF 4/4 | PF 4/6 | PF 4/9 | PF 4/12 | PF 4/12 |

Product detail pictures:

Related Product Guide:

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Leading Manufacturer for Wheel Shot Blasting - Rubber belt Tumble Belt Shot Blast Machines – TAA , The product will supply to all over the world, such as: Uruguay, Poland, Danish, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!