Low price for Automatic Shot Blasting Machine - Blast wheels – TAA

Low price for Automatic Shot Blasting Machine - Blast wheels – TAA Detail:

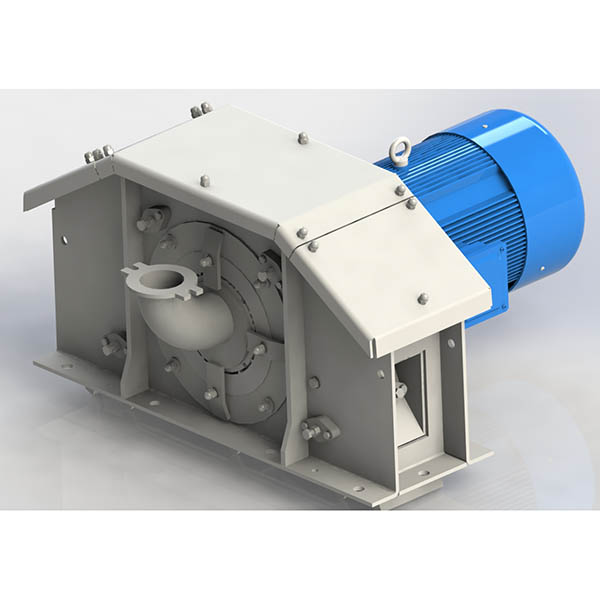

TAA high performance blast wheel have proven themselves on the market to be robust, economically efficient and maintenance-friendly. They are available with different turbine wheel diameters and a variety of spare and wear materials (e. g. hard metal).

TAA high performance blast wheels are very popular for modernizing conventional shot-blasting machines as well.

Product Features

Improving shot blasting speed obviously

Good wear resistance

Reducing energy consumption greatly

Extraordinary service life

Suitable structure

High cleaning quality

Low consumption of steel shot

Low abrasion of parts

Product detail pictures:

Related Product Guide:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for Low price for Automatic Shot Blasting Machine - Blast wheels – TAA , The product will supply to all over the world, such as: Estonia, Denmark, Washington, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

Write your message here and send it to us