New Fashion Design for Shot Peening 316 Stainless Steel - Stainless steel cut wire shot – TAA

New Fashion Design for Shot Peening 316 Stainless Steel - Stainless steel cut wire shot – TAA Detail:

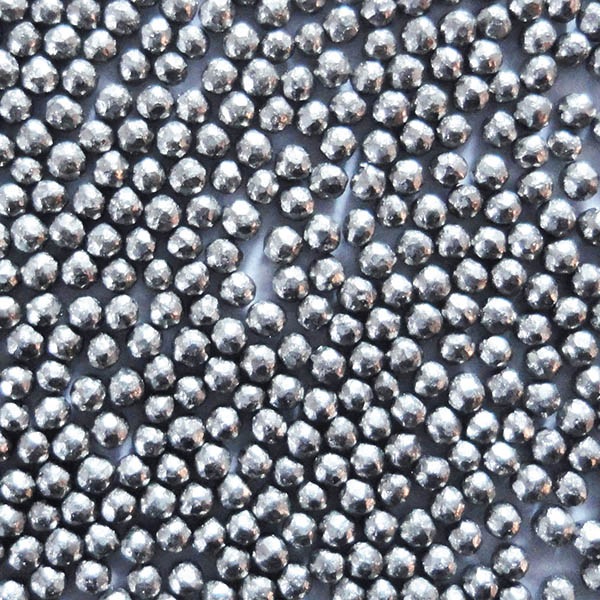

Stainless steel cut wire shot is widely used for the shot/air blasting of various types of non-ferrous metal castings, stainless steel products, aluminum parts, hardware tools, natural stone, etc, highlighting the metal color and achieving smooth, rust-free, matt fi nishing surface treatment eff ect. With good quality stainless steel wire raw material, stainless steel shot is featured with uniform particles and hardness, which guarantees its long service life and good blasting eff ect. The pellets after conditioning have low wear to the blasting machines.

Stainless steel cut wire

Stainless steel cut wire G1

Stainless steel cut wire G2

Stainless steel cut wire G3

Stainless steel cut wire-As cut, cylindrical

G1 Shape-After the treatment for cut surface’s edges, to get the edges passivated

G2 Shape-Semi conditioned

G3 Shape-Get rid of all the edges to make it become ball type, almost spherical

Technical specification

|

SUS304 |

SUS430 |

SUS410 |

|||||

|

Chemical Composition |

C |

≤0.08% |

≤0.12% |

≤0.15% |

|||

|

Si |

≤1.00% |

≤1.00% |

≤1.00% |

||||

|

Mn |

≤2.00% |

≤1.00% |

≤1.00% |

||||

|

S |

≤0.030% |

≤0.030% |

≤0.030% |

||||

|

P |

≤0.045% |

≤0.040% |

≤0.040% |

||||

|

Cr |

18-20% |

16-18% |

11.5-13.5% |

||||

|

Ni |

8-11% |

/ |

/ |

||||

|

Hardness |

HRC38-52 |

HRC25-35 |

HRC20-30 |

||||

|

External form |

Cylindrical/Spherical |

||||||

|

Microstructure |

Austenitic |

Ferrite |

Deformed martensite |

||||

|

Density |

≥7.80g/cm3 |

||||||

Advantages

Produces with very bright surfaces

Dust free surfaces and lower dust when blasting

Longer life than cast abrasives and carbon cut wire shot

No ferrous contamination

No hollow,splits or twins

Available “as cut” or “conditioned”

Available sizes: 0.3mm,0.4mm,0.5mm,0.6mm,0.8mm,1.0mm,1.2mm,1.4mm, 1.5mm

Packing: 25kgs/bag,40bags/wooden pallet or as request.

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with New Fashion Design for Shot Peening 316 Stainless Steel - Stainless steel cut wire shot – TAA , The product will supply to all over the world, such as: UK, Ghana, Florida, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!