Wholesale Dealers of Tumble Shot Blasting Machine - Blast wheels – TAA

Wholesale Dealers of Tumble Shot Blasting Machine - Blast wheels – TAA Detail:

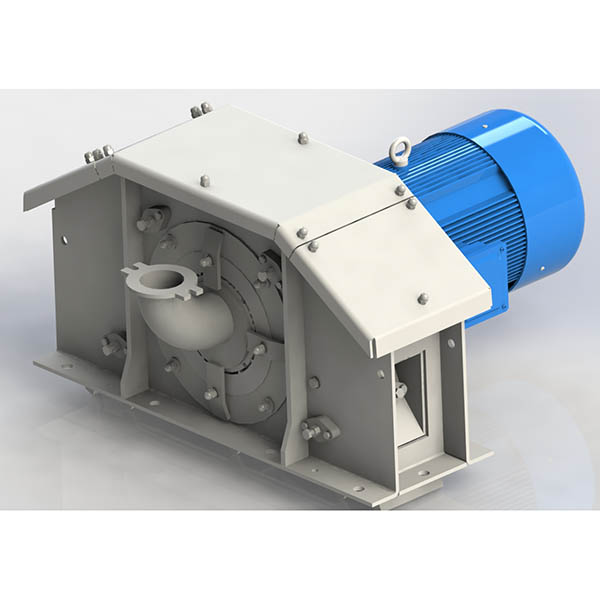

TAA high performance blast wheel have proven themselves on the market to be robust, economically efficient and maintenance-friendly. They are available with different turbine wheel diameters and a variety of spare and wear materials (e. g. hard metal).

TAA high performance blast wheels are very popular for modernizing conventional shot-blasting machines as well.

Product Features

Improving shot blasting speed obviously

Good wear resistance

Reducing energy consumption greatly

Extraordinary service life

Suitable structure

High cleaning quality

Low consumption of steel shot

Low abrasion of parts

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of Wholesale Dealers of Tumble Shot Blasting Machine - Blast wheels – TAA , The product will supply to all over the world, such as: Bolivia, Bangladesh, Indonesia, We have advanced production technology, and pursuit innovative in goods. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you need to be willing to become partners with us. Looking forward to your inquiry.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

Write your message here and send it to us