Rapid Delivery for Side Plate - Blast wheels – TAA

Rapid Delivery for Side Plate - Blast wheels – TAA Detail:

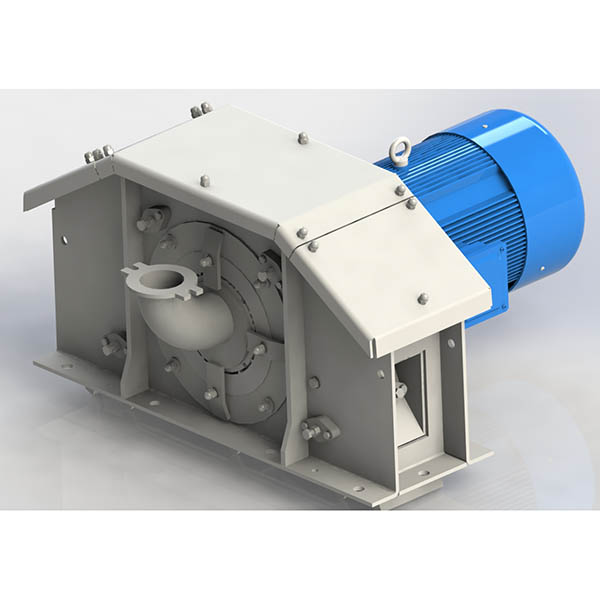

TAA high performance blast wheel have proven themselves on the market to be robust, economically efficient and maintenance-friendly. They are available with different turbine wheel diameters and a variety of spare and wear materials (e. g. hard metal).

TAA high performance blast wheels are very popular for modernizing conventional shot-blasting machines as well.

Product Features

Improving shot blasting speed obviously

Good wear resistance

Reducing energy consumption greatly

Extraordinary service life

Suitable structure

High cleaning quality

Low consumption of steel shot

Low abrasion of parts

Product detail pictures:

Related Product Guide:

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for Rapid Delivery for Side Plate - Blast wheels – TAA , The product will supply to all over the world, such as: Atlanta, Boston, Mecca, We have a large share in global market. Our company has strong economic strength and offers excellent sale service. We have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Write your message here and send it to us