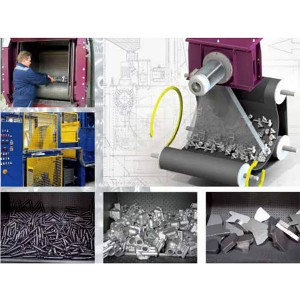

Steel Mill Tumble Belt Shot Blast Machines

Steel mill tumble belt shot blast machines are used for deburring,descaling, sand removal and derusting mass parts. They are operated either as a stand-alone solution or as part of a line. In addition to the standard program, delivers this machine in several sizes and designs. The machines are equipped with the tried and tested high-performance turbines and the maintenance-friendly cartridge filter systems.

Decisive Advantages of Steel mill tumble belt shot blast machines:

AGTOS Blasting technology: AGTOS turbines are solid aggregates that, thanks to fewer wear and tear parts and a higher abrasive flow-rate, work very eff iciently.

Robust construction: Steel mill tumble belt shot blast machines are primarily used in foundries and forges. Large batches with heavy parts place heavy demands on the machine's statics. The combined welding and screwing construction provides the machines with the necessary stability for

long-term use across multiple shifts. The innovative filter technology with its powerful performance.

Low maintenance cost

The innovative filter systerm

A wide range of abrasive types can be delivered on short notice.

Steel Mill Tumble Belt Shot Blast Machines are available in different sizes, including the following standard sizes:

| Technical Specifications | MR270 | MR400 | MR550 | MR750 | MR850 | MR1100 | MR1350 | MR2000 |

| Blasting chamberφ (mm) | 800 | 1000 | 1200 | 1200 | 1400 | 1400 | 1600 | 1600 |

| Width of blasting chamber (mm) | 1370 | 1200 | 1200 | 1650 | 1600 | 2400 | 1800 | 2440 |

| Batch (1) | 270 | 400 | 550 | 750 | 850 | 1100 | 1350 | 2000 |

| Batch (kg) | 1000 | 1000 | 1500 | 1800 | 2500 | 3000 | 3000 | 5000 |

| Max. individuai work piece weight (kg) | 50 | 70 | 100 | 100 | 150 | 150 | 250 | 500 |

| Turbines | 2x11or 15KW | 1x22or 30KW | 1x22or 30KW | 2x22KW | 2x22or 30KW | 3x22KW | 2x30or 45KW | 3x30or 45KW |